Safety leadership wanted to reduce permit errors, ensure compliance with standard procedures, and reduce the administrative effort required to oversee and audit.

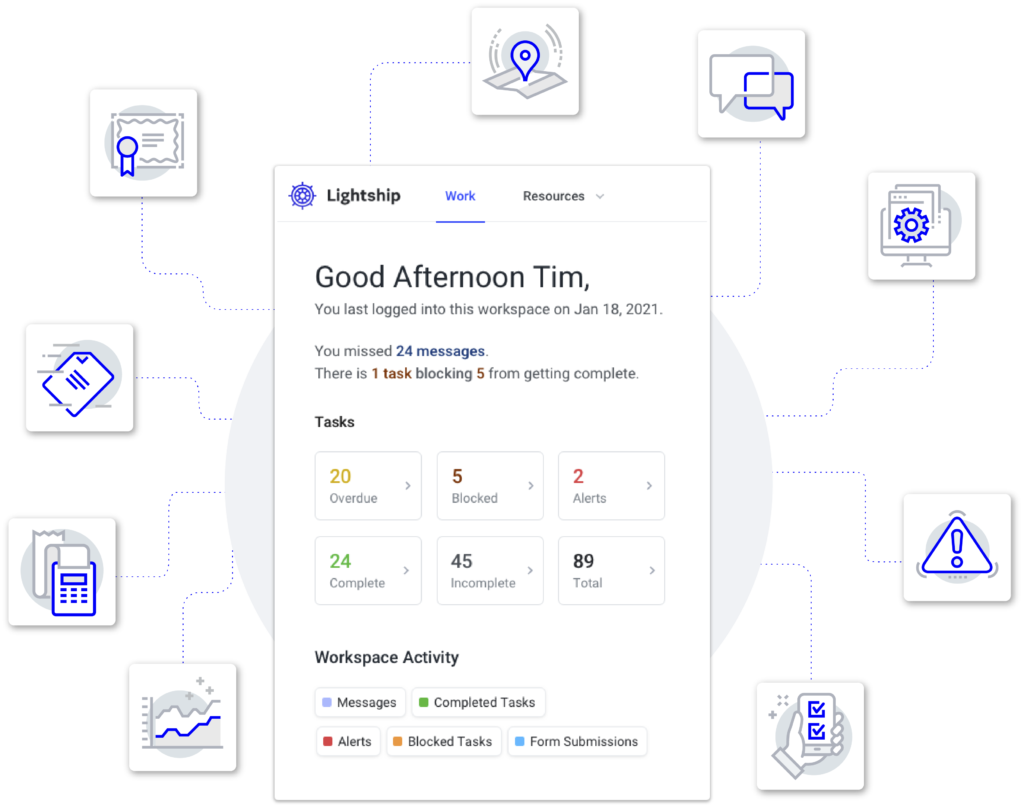

The pulp and paper manufacturer implemented Lightship to organize, coordinate, and automate its hot work management and audit activities.

For example, with Lightship, they were able to:

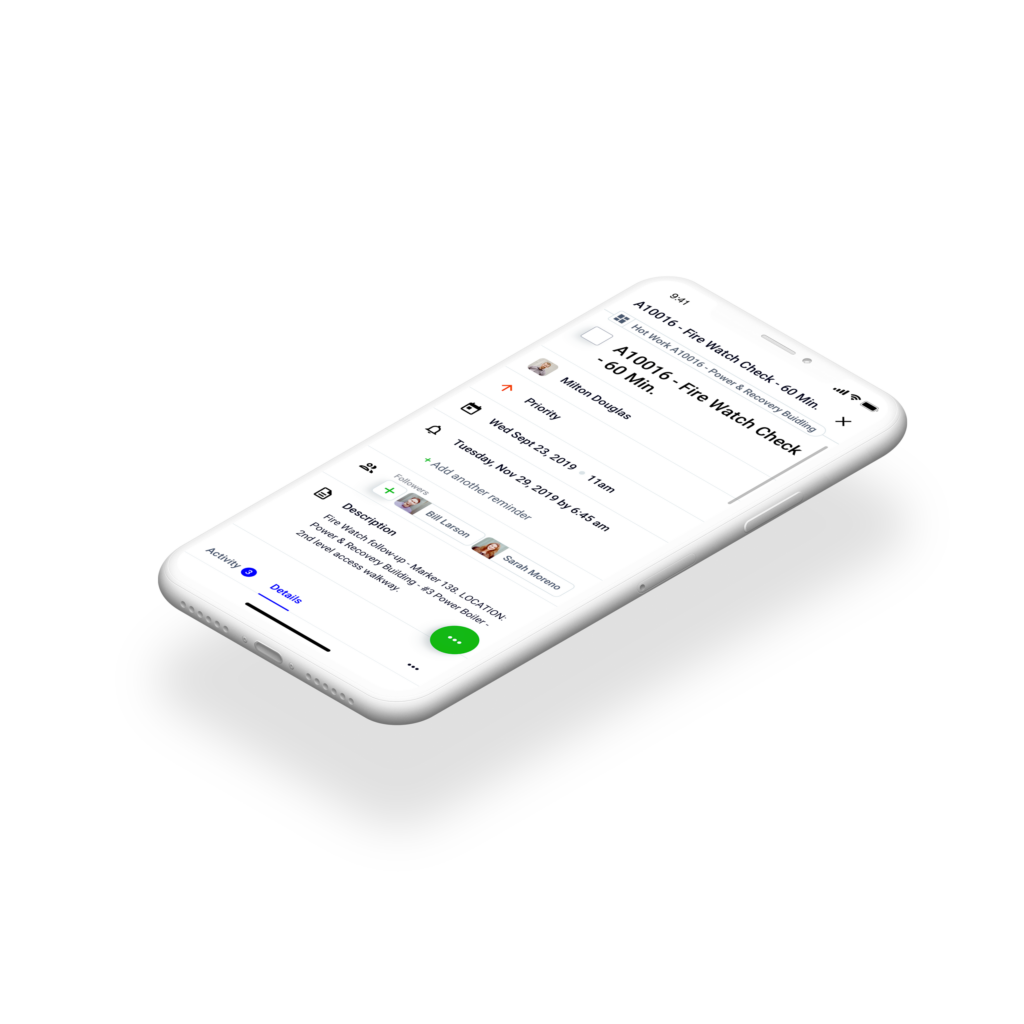

Use interactive mobile forms instead of paper to ensure data capture (and quality), and validate or mandate site-specific procedures.

Automate notifications and work assignments to clearly define roles and tasks, and mandate procedures at the points of creation, approval, activation, and firewatch follow-up.

Validate the proper completion of firewatch follow-up, including exact timelines, people involved, and their location at the time.

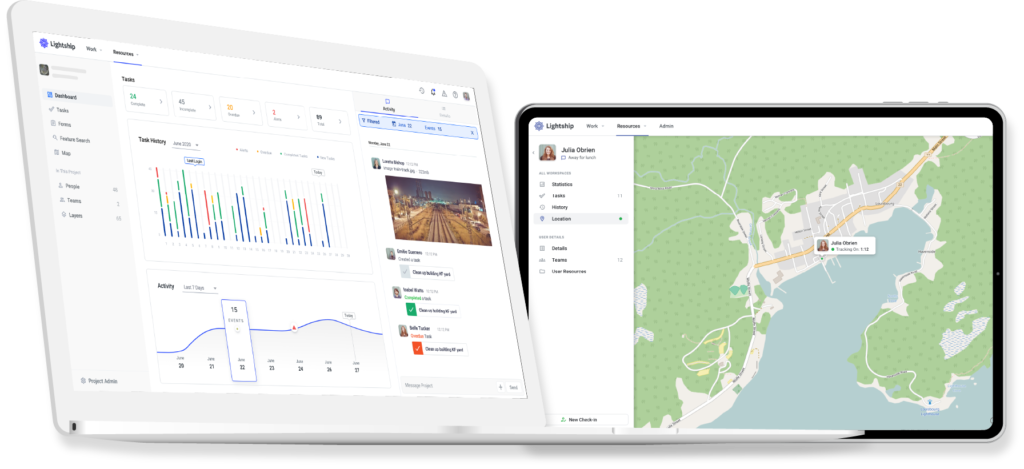

View active permits in real-time, including the exact location to enable and record random site-checks.

Generate high-level summaries for executive planning and insurance reporting.